At previous article we have shown how the Forecasting added value quantified. This is where we apply the concept for optimizing the forecasting process. This allows us to validate how valuable time and resources are used sensibly for demand forecasting.

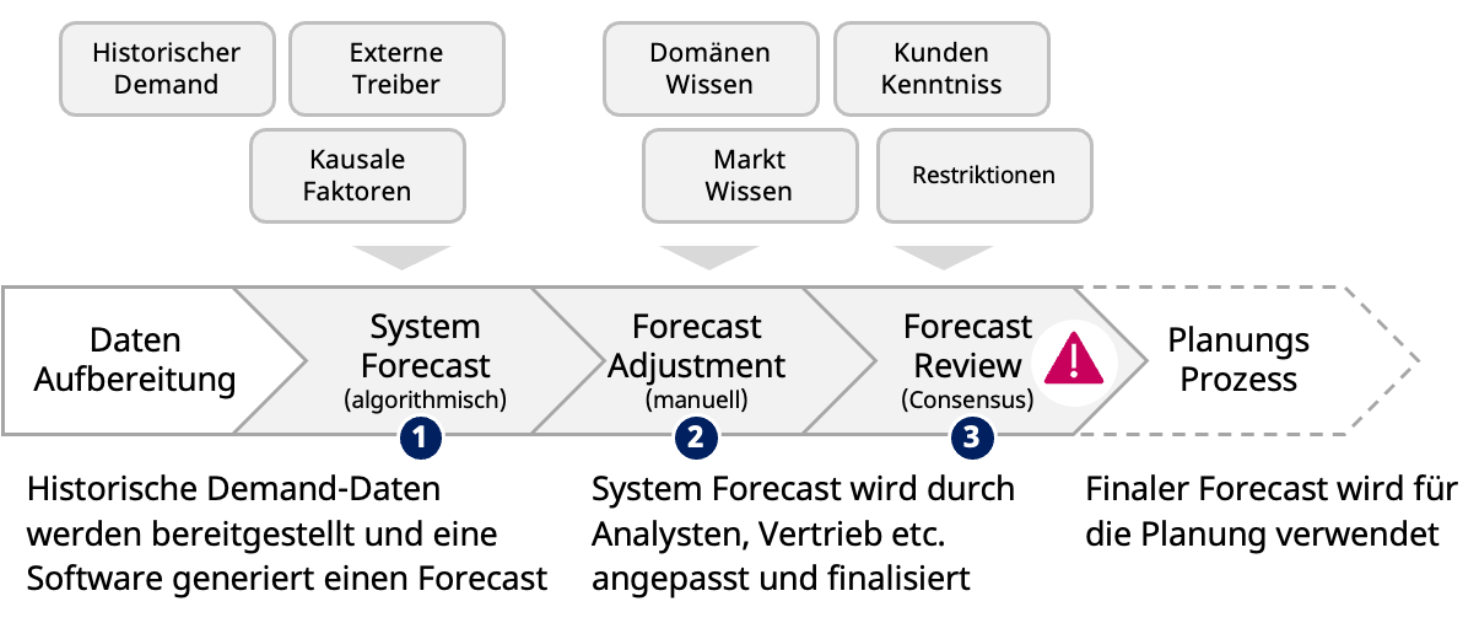

Let's look at a typical demand forecast process. Data is prepared and a system forecast is generated by software. Sales people adjust this system forecast if they think it is necessary. The final demand forecast is finalized e.g. in a monthly planning meeting by a committee and is the input for the planning.

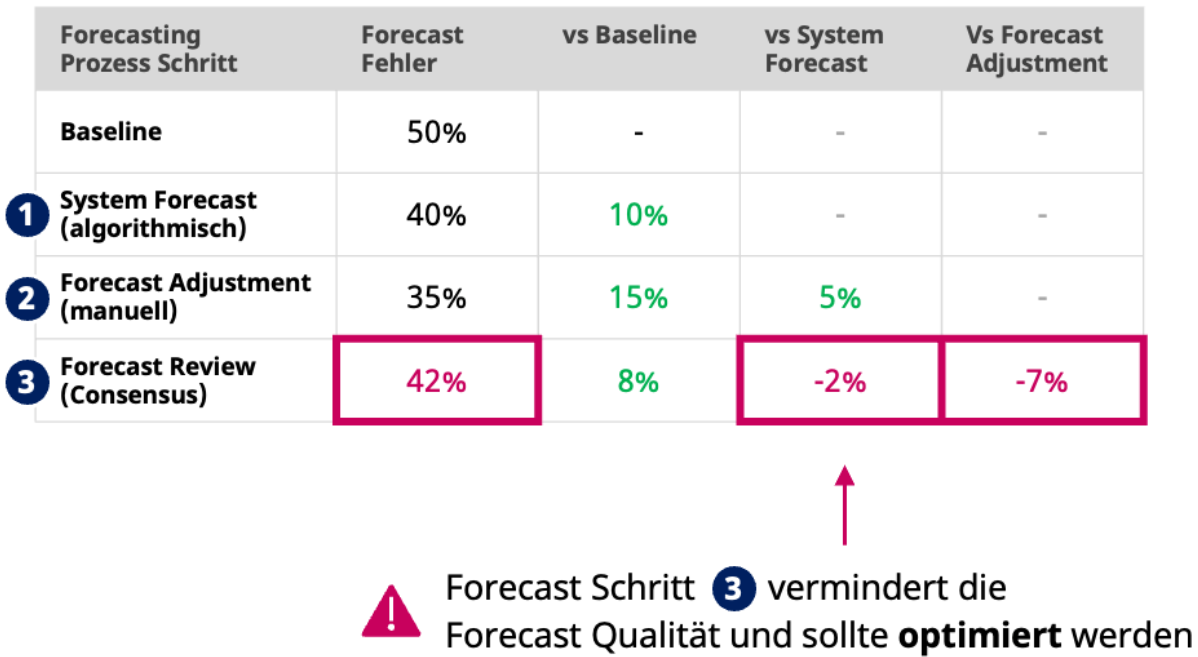

Each of these process steps can be benchmarked against the baseline - again for each item, customer, market, etc. For example, the Baseline Forecast for article A in country DE generates a 50% deviation. The system forecast (1) is only 40% next to the actual demand, thus generating 10% more accurate forecasts.

The analysis shows that the finalization in the Forecast Review (3) affects the forecast quality. This activity should be optimized or eliminated.

In the further parts of this series, we will show you how expert forecasts can be objectified and how they can realize the described analysis in a scalable way.

Let's talk without obligation about how you can Planning reliability and Profitability can optimize through forecasting.

Current information on Best Practices in Forecasting and planning. The Flowtap Newsletter ensures you the decisive competitive advantage.